Leading metal processing machine manufacturer for small kitchen appliances production - Youngmax Machine

Air Fryer Production Line Standard Export Packing Air Fryer Production Line Wholesale - Youngmax

Product Overview

The air fryer production line offered by Youngmax provides exceptional performance to meet the evolving application needs of markets, with advanced technology ensuring high performance.

Product Features

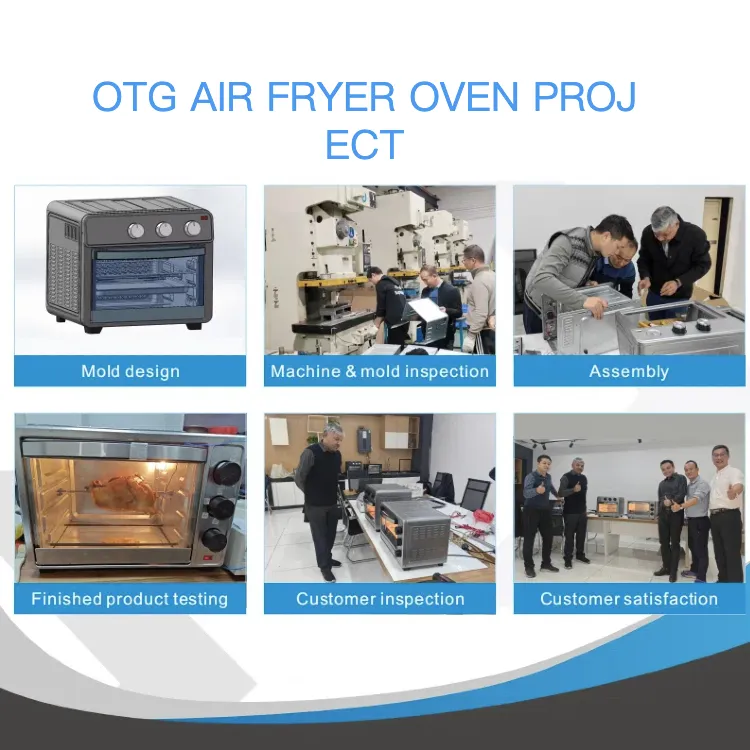

The air fryer production line includes molds, customized hydraulic press machines, and pneumatic punching machines for efficient production. The product line also includes mold design by R&D team, machine and mold inspection before shipment, sample assembly testing, finished product testing, and customer inspection.

Product Value

Youngmax is a reputable production enterprise with experienced experts and strong professional abilities, providing free technical services, manpower, and technical guarantees to customers. The products are widely recognized and exported to regions like Europe, America, Southeast Asia, and the Middle East.

Product Advantages

The air fryer production line can be used for common air fryer, deep fryer, oven, toaster, and OTG products. The pneumatic punching machines in the product line have various capacities, stroke speeds, and die dimensions to meet different production needs.

Application Scenarios

The air fryer production line from Youngmax is suitable for various manufacturing applications, including common air fryer and cooking appliance production. It meets industry standards, customer expectations, and market demands for high-quality and efficient production equipment.