Leading metal processing machine manufacturer for small kitchen appliances production - Youngmax Machine

Turnkey Cookware Manufacturing Line for Non-stick Products

Build Your Own Factory for Frying Pans, Woks, and Cookware Sets

Are you planning to set up a new non-stick cookware production plant or upgrade your current cookware manufacturing line? YoungMax provides a full range of non-stick cookware production line equipment for making frying pans, woks, saucepans, and cookware sets with various coatings (PTFE, marble, ceramic).

From blank pressing to handle assembly, our machines ensure precision, speed, and high ROI for cookware manufacturers.

Non-Stick Cookware Production Line Introduction

This cookware production line supports the manufacturing of non-stick frying pans, aluminum cookware, granite-coated pans, and more.

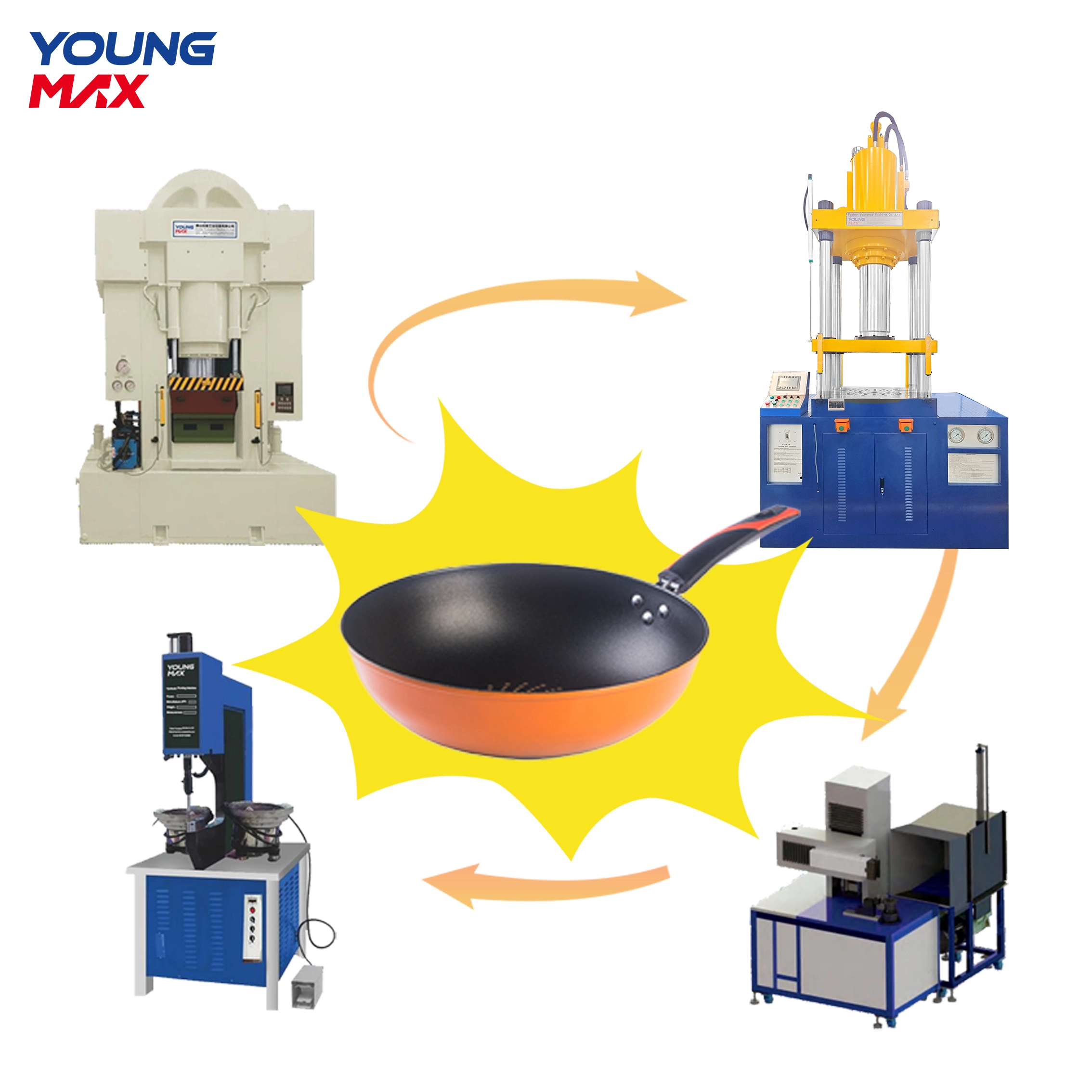

Non-Stick Cookware Production Line process

1,Blank Forming – Hydraulic Press Machine

Deep drawing aluminum or stainless steel sheets into cookware shapes such as pans or pots.

2,Hydraulic Press Machine (Servo Type)

For shaping, flattening, or coating mold preparation. Offers higher accuracy and efficiency.

3,Edge Trimming & Grooving Machine

Creates smooth and safe rolled edges. Essential for cookware durability and safety.

4,Riveting Machine

Automatically assembles handles and accessories. High-speed, low labor cost.

5,Optional: Surface Polishing, Sandblasting, Coating Line (Spray + Bake Oven)

Product Advantage

RELIABILITY: With a 1-year warranty on core components and a 1-year warranty on the machine, you can count on the cookware automatic production line to run reliably and efficiently.

Sales Service: YoungMax can provide professional technical support and a complete solution according to customer's needs.

After-sales service: We provide a wide range of after-sales service, including on-site installation, commissioning and training, on-site maintenance and repair services, online support, video technical support, and engineers to service machines overseas.