Leading metal processing machine manufacturer for small kitchen appliances production - Youngmax Machine

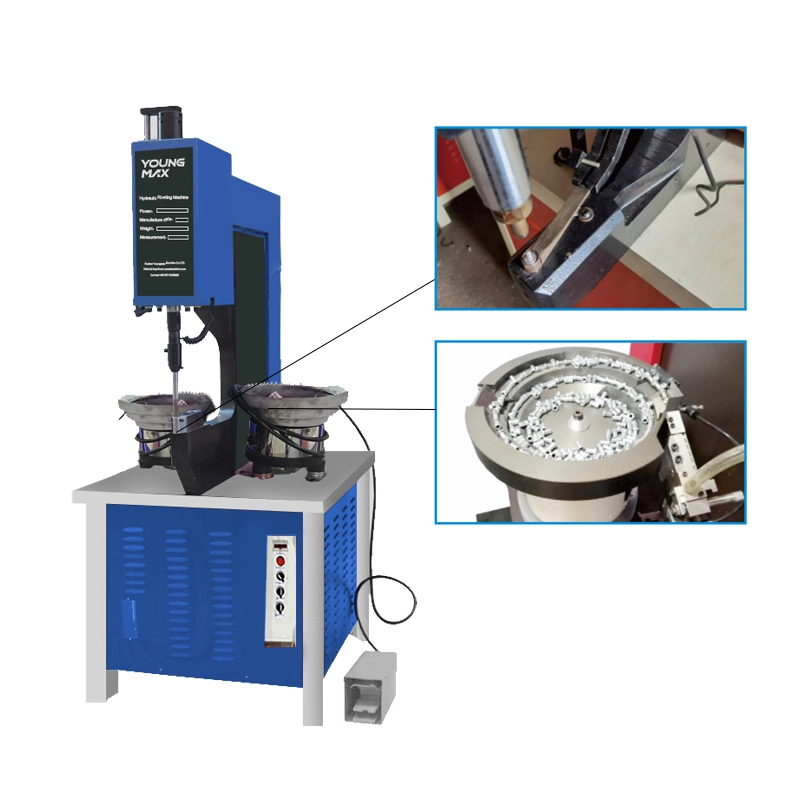

Youngmax cooking pot riveting machine frying pan handle electrical riveting machine metal hydraulic riveting machine

Cooking pot riveting machine metal hydraulic riveting machine

Hydraulic riveting machine is a specialized tool used for the process of riveting, which involves joining two or more pieces of material (usually metal) by inserting a rivet and then deforming its shank to hold the pieces together. Hydraulic riveting machines use hydraulic pressure to generate the force needed to deform the rivet.

Function of Hydraulic Riveting Machine

- Rivet Placement: The machine places a rivet into pre-drilled or punched holes in the materials being joined.

- Hydraulic Pressure Application: The machine uses a hydraulic system to generate a controlled and consistent force to deform the rivet. This force is much greater and more precise compared to manual riveting.

- Rivet Deformation: The hydraulic pressure causes the shank of the rivet to expand, fill the hole, and form a head on the opposite side, thereby securely joining the materials together.

- Control Systems: Many hydraulic riveting machines are equipped with control systems to regulate the pressure, speed, and duration of the riveting process, ensuring consistent and high-quality rivets.

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

PRODUCT FEATURES

1.Capacity:600-700 pcs/hours,used hydraulic press,more high efficiency

2.Screw automatic feeding, more automation&speed up

3.Single &double river, suitable for M4 &M5 Screw

4.Can use for cookware, pressure cooker,bucket and other round shape item

APPLICATIONS

Metal riveting machine is widely used in common cookware, pressure cooker, bucket and many round shape products.

Product specification

|

DESCRIPTION |

YM-YRS01 |

|

Oil pump working pressure |

70kgf/cm² |

|

Total stroke |

100mm |

|

Power stroke |

12mm |

|

Voltage |

380V 50Hz |

|

Power |

2.2KW |

|

Dimension |

750x750x1600mm |

|

Equipment weight |

300KG |

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Get in touch with us

just leave your email or phone number in the contact form so we can send you a free quote for our wide range of designs

Related Products

no data

Copyright © 2025 Foshan Youngmax Machine Co., Ltd -https://www.ymaxmachine.com | Sitemap | Privacy Policy